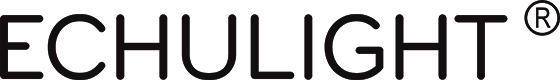

SMD, COB le CSP ke mefuta e meraro ea lesela la LED, SMD ke ea setso ka ho fetesisa, molemong oa ho fihlela litlhoko tse fapaneng tsa bareki, ho tloha ho lifaha tse 5050 ho isa ho theknoloji ea kajeno ea CSP e ntse e ntlafatsoa, mme ho na le mefuta eohle ea lihlahisoa 'marakeng. , mokhoa oa ho khetha har'a lihlahisoa?

Hajoale, SMD le COB li sebelisoa haholo, e 'ngoe le e' ngoe e na le melemo le melemo ea eona le maemo a fapaneng a ts'ebeliso. SMD ke eona e atileng ka ho fetesisa, mefuta e fapaneng ea boholo eo u ka khethang ho eona; COB e ratoa ke 'maraka o nang le linearity e phahameng; le ho tsoaloa ha leseli le lecha CSP, ka lebaka la theknoloji e tsoetseng pele ea ho paka le ho etella pele feshene e ncha ea indasteri. Joale ke bokae ba mofuta oa CSP ha o bapisoa le hlobolisa ea setso COB le SMD strip?

Ts'ebetso ea ho paka ea CSP e tsoetseng pele

LED chip, eo hape e tsejoang e le LED light-emitting chip, ke karolo ea mantlha ea lesela le bonolo la LED, e tla ama ka kotloloho boleng ba leseli la lesela le bonolo la LED. Le mokhoa oa ho senya ambalaji Chip thekenoloji mathata, ke baetsi ba ka sehloohong ba ikitlaelletsa ho senya ka har'a mekoallo botekgeniki.

COB le CSP tse sebelisoang ke thekenoloji ea setso ea ho paka, mohaho o rarahane, o ja nako le mosebetsi o boima, litšenyehelo tsa tlhahiso li phahame. Khanya ea LED e felileng e tla fokotseha ka lebaka la ho senyeha ha mocheso oa thepa ea ho paka le mabaka a mang a ho thibela, ho senyeha ha mocheso o fokolang, le botsitso bo bobe ba sehlahisoa.

Kamora ntlafatso ea tekheniki, chip ea CSP e amohela "flip chip le thekenoloji ea boemo ba chip", e nang le khanyetso e tlase ea mocheso le botsitso bo phahameng ba motlakase. Boholo ba eona bo ntse bo fokotseha, 'me ts'ebetso ea eona e tsitsitse haholoanyane.

Litsenyehelo tsa ho paka ka CSP li tlase haholo ho feta litšenyehelo tsa theknoloji ea khale ea ho paka, e ka bolokang litšenyehelo tsa basebetsi le litšenyehelo tsa ho paka haholo, 'me e boloka chelete e ngata.

Mmala o khanyang o nepahetseng haholo

COB ea setso e amohela ts'ebetso ea phofshoana ea letheba, 'mala o kopanyang leseli ha o hloeke,' mala ha o bonolo ho o laola ha o kopanya leseli, 'me ho lumellana ha mebala ho ka finyelloa feela ka ho tela tekanyo ea lihlahisoa.

Lifaha tsa lebone tsa CSP li hlophisitsoe ka mokhoa o teteaneng, leseli le arotsoe pele le phutheloa, lehlakoreng le khanyang le leholo, ho nepahala ha 'mala o khanyang oa CSP ho phahame, ka ho kopanya mebala e khanyang, CSP ha e bapisoa le COB ea setso, melemo e boetse e totobetse haholoanyane. .

Super Flexibility

COB le SMD ka kakaretso lia tenyetseha, 'me haeba li sa sebetsoe hantle, COB e tla tsoa sephutheloaneng,' me SMD e ka roba sets'oants'o sa lifaha tsa lebone.

Ka lehlakoreng le leng, CSP e bolokehile ebile e ka tšeptjoa hobane ha ho lihokelo tse senyehang habonolo tse kang masakaneng le lithapo tsa khauta, ’me lifaha tsa mabone li sirelelitsoe ka sekhomaretsi sa marotholi. Bophahamo ba chip bo nyane, bo ka etsa leseli le tšesaane le ho feta, angle ea matla ea ho kobeha e nyane, e nang le maemo a matla.

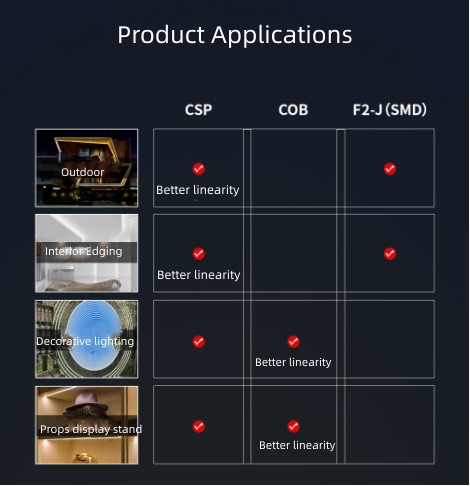

Litlhahiso tse tharo tsa boemo ba tšebeliso ea sehlahisoa

Ho ipapisitsoe le bophahamo bo fapaneng ba lihlahisoa tse 3, ho entsoe karohano e qaqileng haholoanyane ea maemo a ts'ebeliso ea tsona.

SMD strip e sebelisoa haholo ka lebaka la boholo ba eona bo fapaneng bo fumanehang, e loketseng kemiso ea ka hare, mefuta e sa keneleng metsi e ka sebelisoa hape bakeng sa kemiso ea kantle.

COB strip e nang le phello e ntle ea mola, e sebelisoang ho mabone a khabiso le lisebelisoa tse bonts'ang mabone li betere.

CSP strip e na le phello e itseng ea mela le ho fetoha habonolo le ho kobeha. 'Me ka sephutheloana pele ho petsoha leseli, chai e ngata le ho nepahala ha' mala ho molemo ho feta mefuta e 'meli e fetileng ea hlobolisa, ha e le hantle, e theko e boima ka ho fetisisa.

Ka hona, ho latela pono e felletseng, e na le melemo e itseng lits'ebetsong tse fapaneng tsa kahare le kantle. Le boholo ba eona bo kopaneng, bakeng sa lits'ebetso tsa sebaka se moqotetsane melemo e hlakileng haholoanyane.

Nako ea poso: Dec-08-2022